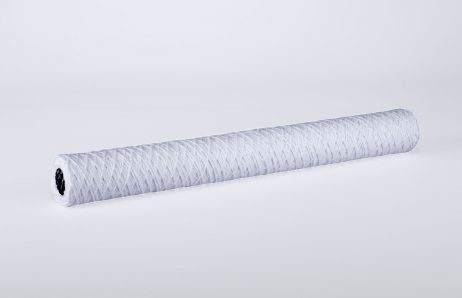

Spool cartridge filters

Spool cartridge filters are generally made of polypropylene soldered onto a base made of the same material.

For filters that must offer chemical resistance, the cartridges are built on a base of stainless steel, onto which the cotton or glass fibres are wound. In this type of cartridge, the liquid moves from the exterior to the interior. They are relatively inexpensive but their impurity retention capacity is relatively low, meaning the cartridges must be replaced more frequently. It is also possible that pollution is released in case of excessive pressure drop.

Principal activity sectors

Formats

- Cartridges from 63.5 mm in diameter, and 10 to 40 inches in length (254 to 1016 mm).

- Available in numerous models with different fittings as DOE, code 3, code 7, code 8

Principal technical characteristics

- Filtration efficiency: 90% for impurities between 0.5 and 150 microns

- Maximum flow of 800 l/h for a 10 inches cartridge

- Recommended pressure difference: 2.1 bars

- Maximum usage temperature:in function of the body and fibre material

Related services

- Provision of consumables

- Rental of filtration units for temporary use or validation of a solution

- Stock management possible